The Kelp Industry

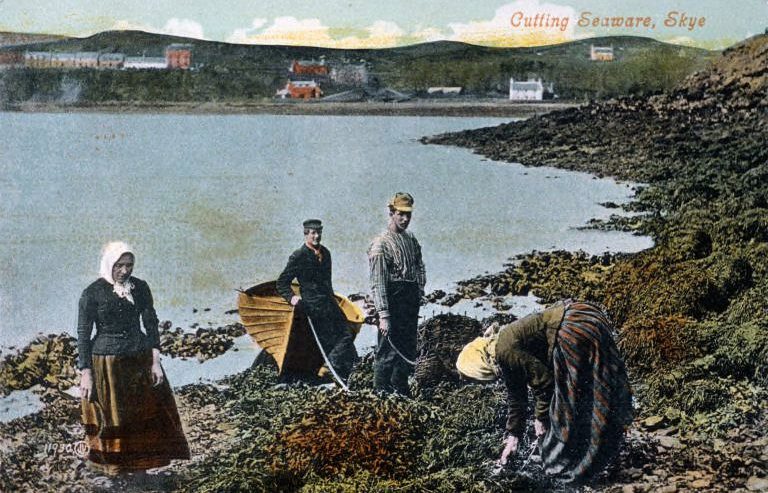

During the Clearances many Highlanders were cleared from the glens and sent to live in new crofting communities, usually near the coast.

Since the crofts were so small tenants would have to work in other industries such as fishing or the kelp industry.

The kelp industry gave work to people who had very little, or no income.

The kelp was heaped into stacks until it was ready to be burned in a kiln or pit.

After a few days drying in the sun and wind, the kelp was turned. When the kelp was dry, it had to be burned to dust.

Employees worked in pairs – one brought the kelp to the kiln, and the other supervised the burning.

Processing kelp

Kelp was harvested in bays and inlets of the sea. It was taken in a creel or by horse and cart to the shore where it was spread out to dry. It was taken in a creel or by horse and cart to the shore where it was spread out to dry. The kelp had to be kept as clean as possible, without sand or other small items dirtying it.

A pile of straw was used to start the fire which would quickly spread across the kiln floor.

Iron rods were used to move and stir up the kelp as it burned.

Each rod was approximately four feet (122cm) long.

The irons were this long to protect the workers’ hands from the great heat coming off the burning kelp.

The rods had to be lifted out of the kiln from time to time to allow them to cool off.

Once the kelp had burned enough, it was pushed to one end of the kiln.

Workers helped each other to do this work, as the burnt kelp was thick, sticky and heavy, like porridge.

There was a pile of wet seaweed kept next to the kiln.

Before the workers went home for the day, some of the wet seaweed was thrown on top of the cooling kelp.

When they returned to the kiln the following day or the day after, the first thing they did was to knock down a wall on one side to expose the kelp to the wind.

Workers harvested more kelp while the burnt kelp was cooling.

Once it had cooled, work would then begin on breaking the kelp into pieces using a hammer or a stone.

Some crofting families owned a pony. The ponies were strong, hardy and of a good nature.

They were often used for jobs around the croft, such as carrying peat or seaweed.

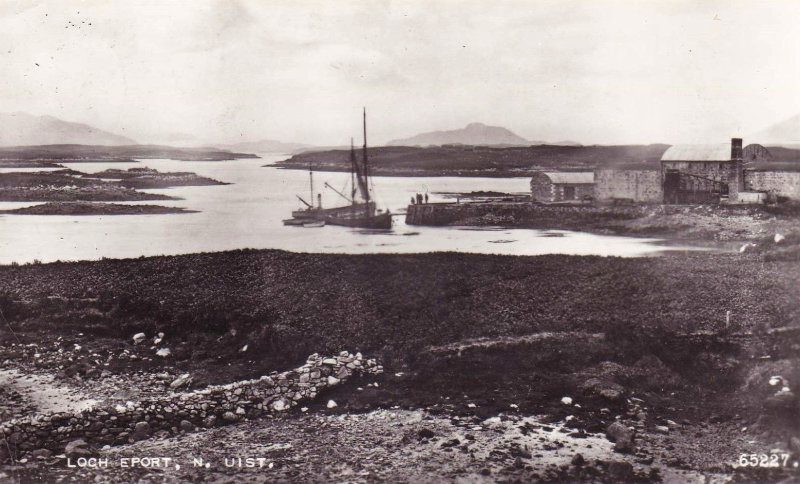

Kelp in North Uist was taken by horse and cart to the pier in Locheport.

There it was weighed before being loaded onto a boat to be taken to the mainland.

Downloads

- 1

- 2

Workers who did not own a horse and cart paid to use someone else’s.